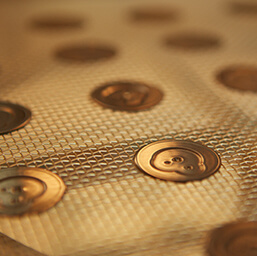

The Craftsmanship behind the Seiko's Enamel Dials

Japanese Enamel

For almost half a century, Mitsuru Yokosawa has been expanding the boundaries of enamel, mastering time-honored techniques and gradually creating new ones. As his experience broadened, the layers of enamel he was able to apply became thinner and thinner. Yokosawa-san is now able to apply a flawless enamel coat just 0.1 mm thin. Such precision requires not only exceptional visual acuity, but also the seemingly magical ability to make minute adjustments to the enamel composition based on fluctuations in humidity and weather conditions. Aptly, it would take the skills of a magician to create the face of the new Seiko Presage.

The Enameling Process

-

Pre-treatment

-

Enamel

Production -

Enamel

Application -

Firing

-

Inspection

and Shipment

The Perfect Fit

The enamel dials are made by the master craftsman Mitsuru Yokozawa and his team. They ensure that the thickness of the enamel is adjusted to perfection to the exact depth required on each part of the dial and that the enamel is perfect for the atmospheric conditions at the time of manufacture so that every dial will last for a lifetime or longer. The sapphire crystals are dual-curved so that even the ridge of the dial can be seen without distortion from any angle. The hour markers are painted no fewer than ten times to lift them in relief from the dial. The tips of the hands are curved by skilled craftsmen to follow the contours of the curved sapphire crystals so that the case depth is minimized. The exhibition case backs are sapphire crystals for greater durability. In these and all other details, the high quality materials and workmanship of Presage are expressed more clearly than ever.