The Master Urushi Lacquer Artist

Urushi Lacquer Artist

Urushi is a type of lacquer processed from the sap of the Japanese lacquer tree. With a history dating back to Japan’s Jomon period (13,100 BCE– 400 BCE), Urushi is said to have been used not only as a coating and ornamentation, but also as an adhesive to bind handgrips to stone axe handles. Urushi was subsequently used for its antiseptic and preservative properties to protect valuable items such as furniture and musical instruments from wear, and was eventually elevated to use as an aesthetic element in works of art. Traditional Urushi lacquerware techniques are still employed throughout Japan.

Of particular renown in Urushi handicraft is the city of Kanazawa in Ishikawa Prefecture, the former Kaga Domain. Maeda Toshitsune, the third feudal lord of the Kaga Domain who lived through the final phase of the turbulent Sengoku period and into the Edo era, summoned renowned craftsmen of all trades from across Japan to the region’s Osaikusho workshops. It is said that the techniques employed by the famed Urushi craftsmen brought to Kaga Domain in this way are the origin of today’s Kanazawa lacquerware. Kanazawa continues to give rise to numerous master craftsmen, boasting a unique tradition of Urushi handicraft incorporating samurai culture and a gold lacquer technique known as Maki-e.

Born in 1957, Isshu Tamura trained in the traditional Kaga Maki-e gold lacquer technique of Kanazawa under master craftsman Ikko Kiyose. After honing his skills in the technique, Mr. Tamura set out to produce unparalleled original works of art. He has executed his technique in Kaga Maki-e not only in lacquerware, but also in the creation of luxury fountain pens and wristwatches which have received worldwide acclaim for their elaborate detail and fine beauty.

-

Metal Polishing

Urushi has been used for centuries as both a decoration and an anticorrosive on metallic objects ranging from armor to tea kettles.

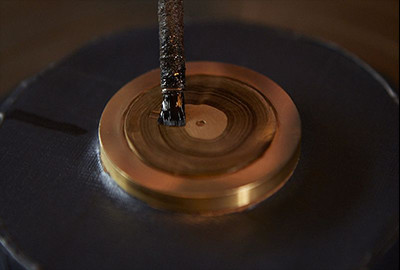

The materials used to craft watch dials are metallic, and the first step in the lacquering process is to polish dial-shaped brass material. As lacquer cannot adhere to smooth metallic surfaces, the polishing process serves to roughen surfaces and allow the Urushi to bond. The material used to achieve this effect is charcoal. While there are several different types of charcoal available for use in this process, the variety used in Presage dials is called Suruga charcoal (after an area in Shizuoka prefecture) and is employed for its fine grain and optimum hardness.

+

+

-

Undercoat, Polishing

Once the metallic surface has been polished, the first coat of Urushi can be applied. This first undercoat is painted on and thinly spread across the whole dial. After the first undercoat is applied, the dial is heated in an oven. Because both the length of time and the temperature at which the dial is heat treated affects the resulting quality, great technique and experience are required to produce a fine product. After the undercoat has dried, the dial is once again polished with Suruga charcoal. This process is repeated a total of three times to ensure even adherence of the Urushi undercoat to the metallic surface.

+

+

-

Intermediate Coat, Polishing

After two weeks and three rounds of undercoat application and polishing, the dial is ready for its intermediate coat. The purpose of the intermediate coat is to provide a thicker coating to bring out the unique deep-black Urushi color. The Urushi used in the undercoat, intermediate coat, and top coat are all sourced from Japan. While both overseas- and Japan-produced Urushi exist, Japan-sourced Urushi boasts higher quality coating properties which result in a unique depth in the finished product. This step is crucial in defining the product’s finished image.

+

+

-

Top Coat, Polishing

The application of the top coat is the last coating step in realizing the finished product. This final step involves adjusting the thickness of the intermediate coat to create a look and feel befitting the watch’s style. Great skill and experience is required to create a smooth and even surface, and even greater patience and focus is necessary to ensure precise application around the entire dial. This is where craftsmen can fully demonstrate their years of experience and intuitive knowledge.

Once the top coat has been applied, the dial is polished first with Suruga charcoal and then with both rough and fine grits of whetstone powder in a multi-step process until the desired texture is achieved. This process allows for an even greater level of smoothness. Next, a layer of Suri Urushi, a lacquer which turns clear when dry, is applied and the dial is readied for the next step.

+

+

-

Finished Polishing, Suri Urushi

By this stage, the dial has been thoroughly coated in Urushi and displays the characteristic deep-black color. The finished polishing step is carried out using a compound selected specifically to be used with Urushi, and is done to further enhance the lacquer’s color and wipe away any fine scratches. Finally, an extremely thin layer of Suri Urushi is applied to fill in any minute scratches or pinholes unable to be removed in the former process.

+

+

-

Buffing

After coating and polishing, the dial is ready for the final finishing step. In this process, Mr. Tamura coats his finger in a special powder to buff the surface of the Urushi lacquer dial. Relying on his delicate skill and intuition, Mr. Tamura carefully works on the dial surface to bring out the Urushi’s innate appeal. This buffing step allows him to perform a final check of the Urushi’s luster and thickness as he also looks out for any remaining scuffs or pinholes. This step truly showcases the skill of a master. The finished Urushi lacquer dial will contribute its distinct Urushi color and hand-crafted individuality as a component of the watch.

+

+

-

Selected Tools of the Trade (Maki-e)

The tools used in Maki-e are extremely rare, with only a handful currently in existence. Often, the tools lacquer artists use in their craft, such as brushes and thin Funzutsu tubes, are made by the craftsmen themselves. Mr. Tamura’s makes his brushes from bamboo grass from the mountains of Kanazawa, fitting them with brush heads and using them as an extension of his hand. Because the brushes are handmade, not all of them satisfy Mr. Tamura’s strict standards. Out of twenty brushes, he chooses only two or three to work with. He also uses spatulas made with human hair bound with animal glue, a tool he values for its particular smoothness.

+

+

-

Selected Tools of the Trade (Urushi Handicraft)

A variety of tools are employed in Urushi handicraft, some of which are quite unique. One type of brush uses downy hairs taken from the roof rat, a material which is exceptionally hard to obtain but provides for a brush with a premium feel. The shaft of a crane feather is used as a tube for scattering powder materials, whale baleen for a spatula, and sea bream teeth to polish gold. The artisans’ tools are truly the product of creative and inquisitive minds.